A new coating for glass developed by Rice University researchers and collaborators could help reduce energy bills, especially during the cold season, by preventing heat loss from leaky windows. The material ⎯ a transparent film made by weaving carbon into the atomic lattice of boron nitride ⎯ forms a thin, tough layer that reflects heat, resists scratches and shrugs off moisture, UV light and temperature swings.

The researchers simulated how the material would behave in an actual-sized building in cities with cold winters like New York, Beijing and Calgary, showing it improved energy savings by 2.9% compared to existing alternatives. With over 4 billion square feet of new windows installed annually in the U.S. alone, the savings can add up.

According to a study published in Advanced Materials, the coating’s durability allows it to be placed on the exterior-facing side of the glass ⎯ a major advantage over conventional low-emissivity (low-E) coatings. Emissivity describes a material’s ability to radiate heat as thermal energy; lower values mean less heat escapes through the glass. Traditional low-E coatings are prone to degradation from environmental factors like humidity and temperature fluctuations, which requires them to be placed on windows’ interior-facing side.

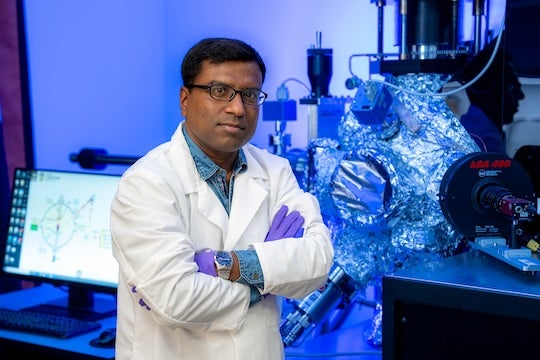

“Although pure boron nitride shows almost similar emissivity to glass, when you add a little amount of carbon into it, the emissivity lowers significantly ⎯ and this changes the game altogether,” said Pulickel Ajayan, Rice’s Benjamin M. and Mary Greenwood Anderson Professor of Engineering and professor of materials science and nanoengineering.

To create the coating, the team used pulsed laser deposition, a technique in which short, high-energy laser bursts strike a solid boron nitride target, sparking plasma plumes that disperse into vapor then settle onto a substrate ⎯ in this case, glass. Because the process takes place at room temperature, it avoids the high heat typically required for making adhesive coatings.

“From the synthesis point of view, coating boron nitride on glass is truly amazing and very exciting,” said Abhijit Biswas, lead author on the study and an expert in thin film synthesis.

Ajayan noted the same low-temperature boron nitride deposition technique could be adapted for other materials besides glass, including polymers, textiles and possibly even biological surfaces. Moreover, other scalable techniques ⎯ such as roll-to-roll chemical vapor deposition or sputtering ⎯ could eventually make commercial production feasible with the right process optimization.

“This broadens the application space for boron nitride coatings significantly,” said Ajayan, who is the corresponding author on the study. Researchers in his group at Rice have been studying boron nitride thin film growth for years, interested in the material’s standout mechanical, thermal and optical properties.

From a raw materials standpoint, boron nitride is less expensive than the silver or indium tin oxide used in most commercial low-E glass. Still, the researchers caution against direct cost comparisons, since the materials differ in durability, processing methods and technological maturity. Even so, the team sees promise in the coating’s long-term performance, especially in harsh environments where existing materials fall short.

To evaluate the coating’s optical clarity and potential for energy savings in buildings, the Rice team partnered with Yi Long, a co-corresponding author from the Chinese University of Hong Kong, whose group focuses on functional materials for smart window technologies. Long emphasized the coating’s durability in outdoor conditions as a key distinction from existing technologies.

“The high weatherability makes it the first outdoor-facing low-E window coating, with an energy-saving capacity that clearly outperforms the indoor-facing counterpart,” Long said. “It could be an excellent solution in densely built environments.”

Shancheng Wang also contributed significantly to the research, particularly around the energy-saving angle.

“The transparency level and promising low emissivity makes carbon-doped coated glass a competitive energy-saving option for cities like Beijing and New York,” Wang said.

In addition to Rice and the Chinese University of Hong Kong, the team included collaborators from Arizona State University, Cornell University and the University of Toronto.

The research was supported by Air Force Office of Scientific Research (S004434-AFOSR); Air Force Office of Scientific Research and Clarkson Aerospace Corp. (FA9550-24-1-0004); the Rice Space Institute; the Department of the Navy, Office of Naval Research (N00014-22-1-2357); the U.S. National Science Foundation (1650114, 1626418, DMR150006); DEVCOM Army Research Laboratory; the U.S. Department of Defense High Performance Computing Modernization Program; the U.S. Department of Energy (DESC0021230); the Natural Sciences and Engineering Research Counsel of Canada; the Canada Foundation for Innovation; the Government of Hong Kong Special Administrative Region; the Chinese University of Hong Kong; 2024 Shenzhen-Hong Kong-Macau Science and Technology Program (SGDX20230821094659005) and Innovation and Technology Fund (ITS/221/23). The content herein is solely the responsibility of the authors and does not necessarily represent the official views of the funding organizations and institutions.

- Peer-reviewed paper:

-

Carbon Doped Boron Nitride Nano-Coatings for Durable, Low Emissivity Glass Windows | Advanced Materials | DOI: 10.1002/adma.202507557

Authors: Abhijit Biswas, Shancheng Wang, Cody Milne, Gustavo Alvarez, Md Akibul Islam, Tymofii Pieshkov, Tanguy Terlier, Tao Li, Jishnu Murukeshan, Tia Gray, Jaejun Lee, Robert Vajtai, Yuji Zhao, Tobin Filleter, Zhiting Tian, Arunima Singh, Yi Long and Pulickel Ajayan

https://doi.org/10.1002/adma.202507557