A new one-step, water-, acid- and alkali-free method for extracting high-purity lithium from spodumene ore has the potential to transform critical metal processing and enhance renewable energy supply chains. This study was published in Science Advances Oct. 3.

As the demand for lithium continues to rise, particularly for use in electric cars, smartphones and power storage, current extraction methods are struggling to keep pace. Extracting lithium from salty water is a lengthy process, and traditional methods that use heat and chemicals to extract lithium from rock produce significant amounts of harmful waste.

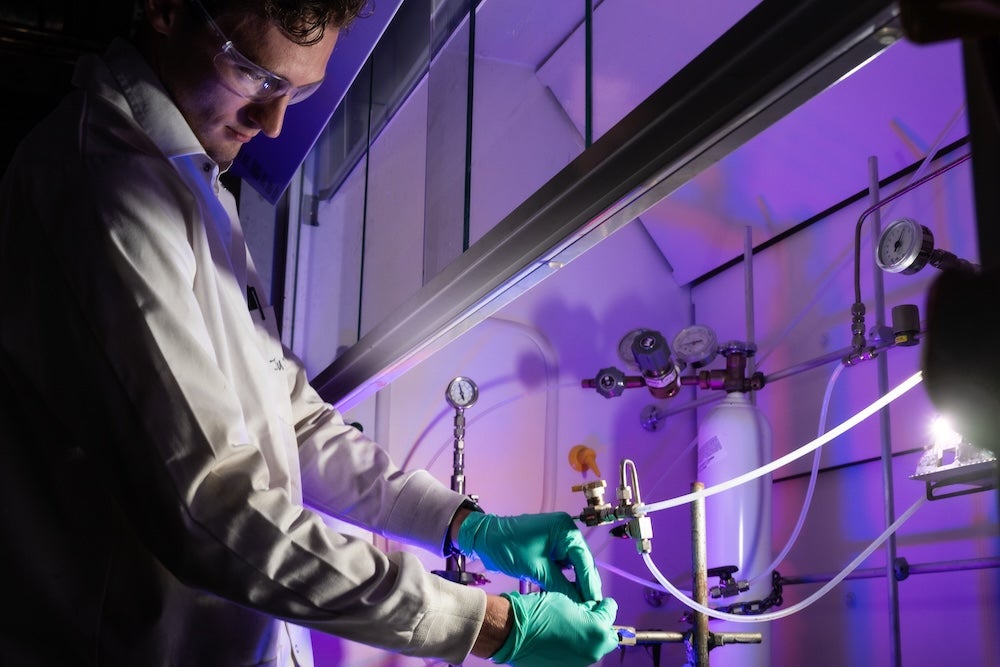

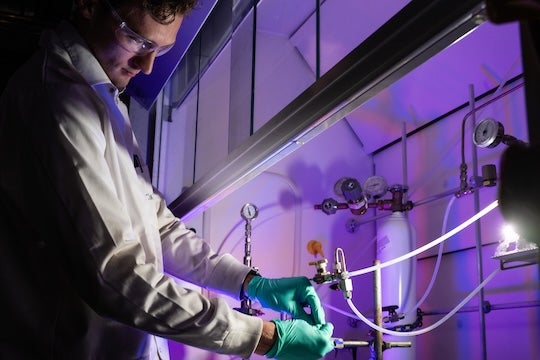

Researchers led by James Tour, the T.T. and W.F. Chao Professor of Chemistry and professor of materials science and nanoengineering at Rice University, have developed a faster and cleaner method using flash Joule heating (FJH). This technique rapidly heats materials to thousands of degrees within milliseconds and works in conjunction with chlorine gas, exposing the rock to intense heat and chlorine gas, they can quickly convert spodumene ore into usable lithium.

“This method reimagines how to harvest lithium from its most abundant ore, spodumene, a material that is abundant in the U.S.,” said Tour, co‑corresponding author of the study. “We can leapfrog monthslong water evaporation pools and dayslong acid leaching and then directly generate lithium chloride.”

Hypothesis, experiments and the novelty of approach

Guided by thermodynamic calculations, the researchers exposed α-spodumene, a naturally occurring hard-rock lithium mineral, to FJH and chlorine gas. This one-step process eliminates the need for the traditional multistep acid roasting method, allowing lithium to be extracted directly as lithium chloride.

With a flash of electrical current, the mineral shifted from its stable α-phase to the high temperature-accessed β-phase, making lithium available for reaction with chlorine gas. The lithium then vaporized as lithium chloride, while aluminum and silicon compounds were left behind. All of this was complete within seconds.

“Present techniques rely on multistep, chemically intensive treatments,” said study co‑corresponding author Yufeng Zhao, an associate professor of physics at Corban University and visiting professor at Rice. “The unique aspect of this method is the combination of rapid, uniform heating and favorable thermodynamics, which together enable practical and selective extraction.”

Traditional methods, from acid roasting to brine evaporation, simply weren’t designed for ultrafast separation, said Shichen Xu, the first author of the study and a postdoctoral researcher at Rice.

“Our controlled, rapid-heating approach overcomes kinetic barriers that have hindered single‑step extraction for decades,” Xu said.

Findings and broader significance

The researchers achieved nearly instantaneous lithium extraction from spodumene, producing lithium chloride with 97% purity and 94% recovery, significantly outperforming traditional methods that can take days to months.

“This method paves the way for local, small-footprint lithium processing units or large-scale units for massive waste mining operations,” said Justin Sharp, co-first author and research assistant. “It’s a real paradigm shift. We can now envision battery-grade lithium production without acids, without large waste outputs and without waiting weeks.”

Additionally, a startup from Tour’s lab, Flash Metals USA, is already scaling this technology for metals extraction from waste.

“They would be able to rapidly implement this method into their production line once their pilot plant begins operation early next year,” Sharp said.

Environmentally, the elimination of acid and alkali significantly reduces waste burden. Economically, shorter processing times and simpler infrastructure could lower costs and decentralize lithium supply. Academically, the work demonstrates the rapid, acid-free extraction of lithium from natural ore, raising possibilities for applying FJH and chlorine gas to other strategic minerals.

Co-authors of the study include Rice’s Alex Lathem, Qiming Liu, Lucas Eddy, Weiqiang Chen, Karla Silva, Shihui Chen, Bowen Li, Tengda Si, Jaeho Shin, Chi Hun Choi, Yimo Han, Kai Gong and Boris Yakobson, along with Yufeng Zhao from Corban University.

The study was supported by the Defense Advanced Research Projects Agency, the Air Force Office of Scientific Research and the U.S. Army Corps of Engineers.