Irregular heartbeats affect more than 4 million Americans, and for many, the treatment is cardiac ablation — a procedure that uses long, flexible catheters inserted through blood vessels to modify small areas of the heart and restore a normal rhythm. It is a routine yet delicate procedure that requires constant real-time ultrasound imaging from within the heart.

One of the major challenges of the procedure is keeping the imaging catheter in place: In operating rooms across the country, a second surgeon or technician is often stationed bedside solely to hold the catheter steady. That is the problem six Rice University students — working together as team AnchorCat — set out to solve with their senior engineering design project.

“As it is currently conducted, the procedure entails very inefficient use of skilled medical personnel, and our goal was to develop a more robust solution,” Vivian Lang said.

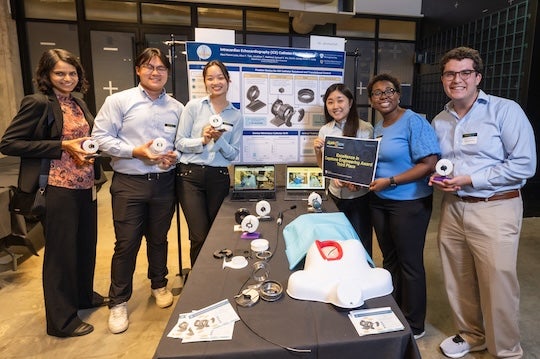

Lang and teammates Alexi Pierre-Louis, Sam Wu, Jonathan Makhoul, Sumin Jeong and Alice Tian developed a device that holds and stabilizes an intracardiac echocardiography catheter during heart procedures, allowing the primary physician to maintain precise control of the catheter without needing a second set of hands.

The problem itself was brought to the Oshman Engineering Design Kitchen as a challenge by a team of physicians and engineers at the Texas Heart Institute (THI). Dr. Mehdi Razavi, who leads the Electrophysiology Clinical Research and Innovations lab at THI, and Dr. Feng Gao served as the team’s clinical mentors, offering feedback every step of the way. Members of Razavi’s team who worked with the students include Allison Post, Lukas Jaworski, Mathews John and Drew Bernard. Weekly check-ins helped shape the design and the students’ understanding of how clinical needs translate into engineering decisions.

“We were all extremely lucky to work with such talented, motivated students,” Gao said. “This is a testament to not just their strong engineering foundation but also exceptional team-building and problem-solving skills. We are excited to see where this leads.”

Wu said one of the biggest challenges the students faced was precisely navigating from “the medical side of the problem into the engineering side of the problem” through what initially seemed a daunting and seemingly limitless design space.

The team’s final device consists of a wide, weighted base to keep the system stable, a rotator with a ratcheting mechanism to allow precise torque control and a fixator that locks the catheter handle into place while preserving access to its built-in dials. Throughout the design process, the students constantly refined their work — and occasionally had to step back and rethink their approach entirely.

“We had some really big, radical device prototype adjustments,” Lang said. “The first semester we had this big articulating arm — it was very bulky and complex. Then the second semester, we decided to just scrap all of that and reduce it down to the sleekest, smallest version of our device.”

The result was a fully functional, high-fidelity 3D-printed prototype made of a type of plastic known as polylactic acid and commercial springs and bearings that had already been tested in a porcine model at THI. The team filed a provisional patent, formed an LLC and is now in conversations with medical device companies to license the design.

The hands-on, real-world nature of the capstone project left a lasting mark on all six team members, influencing their plans and sharpening their goals. Wu, for instance, is heading to the University of Texas Southwestern for medical school in the fall.

“Through this experience, I found a role model in Dr. Razavi for the kind of doctor I want to be in the future,” he said. “Before working with him, I knew I wanted to go into medicine and that I wanted to do research and make these life-changing discoveries in the lab. But I did not really know how I would work my engineering degree into that.”

Now, Wu says he sees a clear path — one that combines clinical insight with technological innovation.

The project also reinforced the kind of community the students found at Rice, especially within the Department of Bioengineering.

“I really enjoyed my time at Rice,” said Pierre-Louis, who has a summer internship lined up at the University of Texas MD Anderson Cancer Center’s Ideation and Development Ecosystem for Advancements Lab and is returning to Rice for a one-year master’s in the Global Medical Innovation program. “If I had to do it all over again, Rice would still be my pick.”

The team credits much of their success to that close-knit atmosphere — and to a group dynamic built on trust, collaboration and, as Lang noted, “a lot of Costco snack runs.”

Tian will pursue a dual medical and engineering degree at Texas A&M University, while Makhoul is headed to a doctoral program in biomedical engineering at University of Colorado Boulder. Jeong plans to pursue a master’s degree at Northwestern University, while Lang is taking a gap year while applying to medical school.

Team AnchorCat won third place at the 2025 Huff OEDK Engineering Design Showcase and competition and was a finalist in the national Design of Medical Devices Conference. Their faculty mentors said the team’s success is no accident.

“Team AnchorCat has done exceptionally well, and I think theirs is a story worth telling,” said Sabia Abidi, assistant teaching professor in bioengineering.

The project was supported by Harrell Huff and the resources of the OEDK.