A team of Rice University students has developed a cold spray metal 3D printing device that relies on pressure and velocity rather than temperature to create a metal part. Their work could help expand the repertoire of metal additive manufacturing techniques, bringing down cost and enhancing the quality of making or repairing one-off complex metal parts.

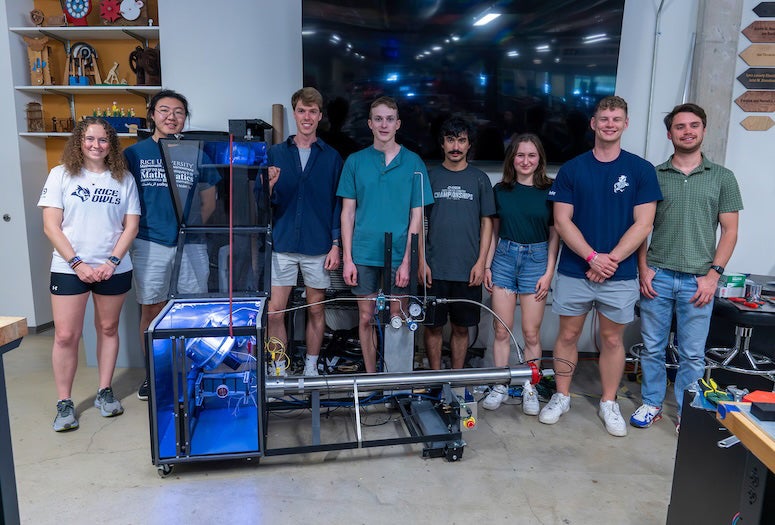

Team AeroForge members ⎯ Eli Case, Julianna Dickman, Garrett French, Galio Guo, Douglas Hebda, Grant Samara, Davis Thames and Aasha Zinke ⎯ used the device to successfully deposit copper, demonstrating the viability and potential of their prototype. The project won an Excellence in Capstone Engineering Award and first place in the Willy Revolution Award for Outstanding Innovation at the annual Huff OEDK Engineering Design Showcase, which took place April 11 at the Ion.

“We’re very excited and very relieved,” Dickman said. “We spent many late nights in the Oshman Engineering Design Kitchen, and it feels very rewarding to get recognized for our work.”

Guo said that when the team did not win its category award, he thought it was not going to win anything.

“Then we won the first award, and I was really happy, and when we won the second award, I was really, really happy,” Guo said.

Team AeroForge’s project is also the recipient of this year’s Hershel M. Rich Invention Award, presented to Rice engineering students or faculty members for “original invention development.”

“Traditional metal 3D printers generally use a laser to melt metal powder into a particular shape, but melting can really impact the properties of your product,” Zinke said. “Cold spray technology, which has been used for coatings, uses velocity instead of heat, basically accelerating metal particles so fast that they adhere to and deform onto a substrate. The system that we’ve designed aims to accomplish that in a 3D printing capacity.”

Applications for the device include the manufacture and repair of metal parts with a complex structure, such as components used in industrial assembly lines or in vehicles or aircraft. Industries that rely on metal components ⎯ automotive, oil and gas, defense ⎯ can incur significant losses as a result of supply chain disruptions, so the team hopes its device can provide a viable, low-cost alternative for making or repairing parts on demand.

Thames, who first pitched the idea for the project to a teammate almost a year prior to the start of the senior design class, explained the advantages of using the cold spray metal 3D printer over welding.

“Typically with repairs, you can only remove material as you reshape a metal part,” Thames said. “But with this process, you can add material, and then machine it back down. With welding, for instance, varying melting temperatures may result in uneven material properties. We don’t have that issue with this device.”

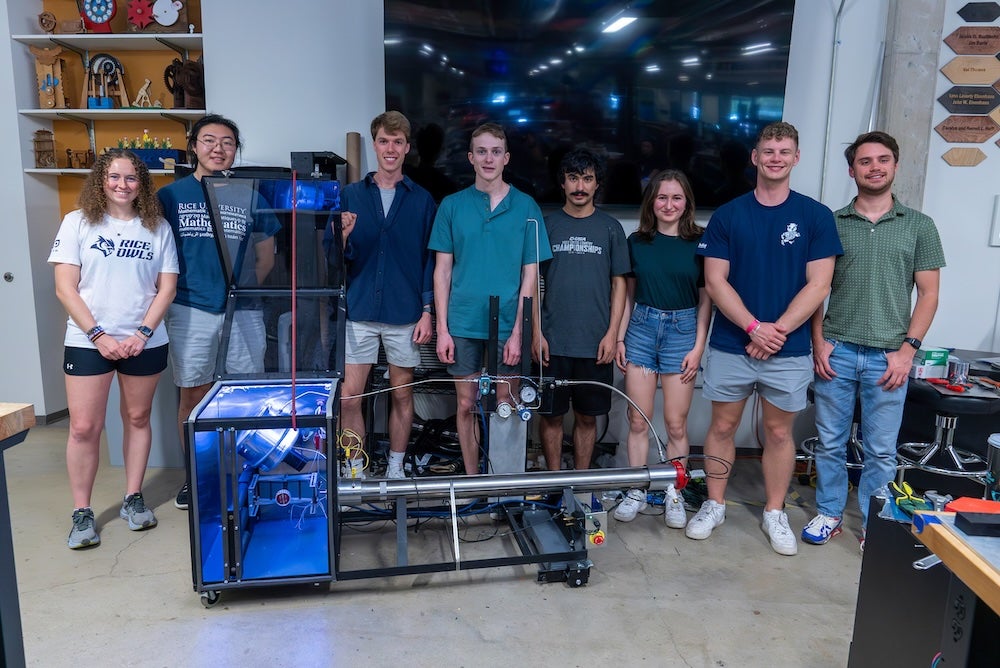

The device consists of a gas tank that feeds high-pressure nitrogen gas into the system; controls that regulate valves and monitor pressure and temperature; a pressure vessel, which heats the gas to 450 Celsius (842 Fahrenheit); a powder feeder designed to dispense metal powder into a nozzle at a precise rate; and a custom nozzle.

Dickman explained that while the gas does get heated, “it is still a cold spray system because when the gas meets powder in the nozzle, it is expanded out of the nozzle and cools very quickly.”

“The particles never melt, they really never see temperature ⎯ the temperature only serves to increase the speed of the gas, which imparts its momentum on the metal powder, which can then accelerate to our substrate and adhere,” Dickman said.

A lot of the team’s efforts was focused on reducing costs, since most metal 3D printers can cost over $1 million. Team AeroForge built its device for less than $5,000.

“One of our big innovations here is making the system so much cheaper,” Samara said. “A lot of our parts were machined in house, for instance the pressure vessel, because that’s potentially a very dangerous thing. Other parts, like the nozzle, are proprietary, so it’s not something that you can find elsewhere. The nozzle is a very difficult part to manufacture, we had to develop new processes to make it.”

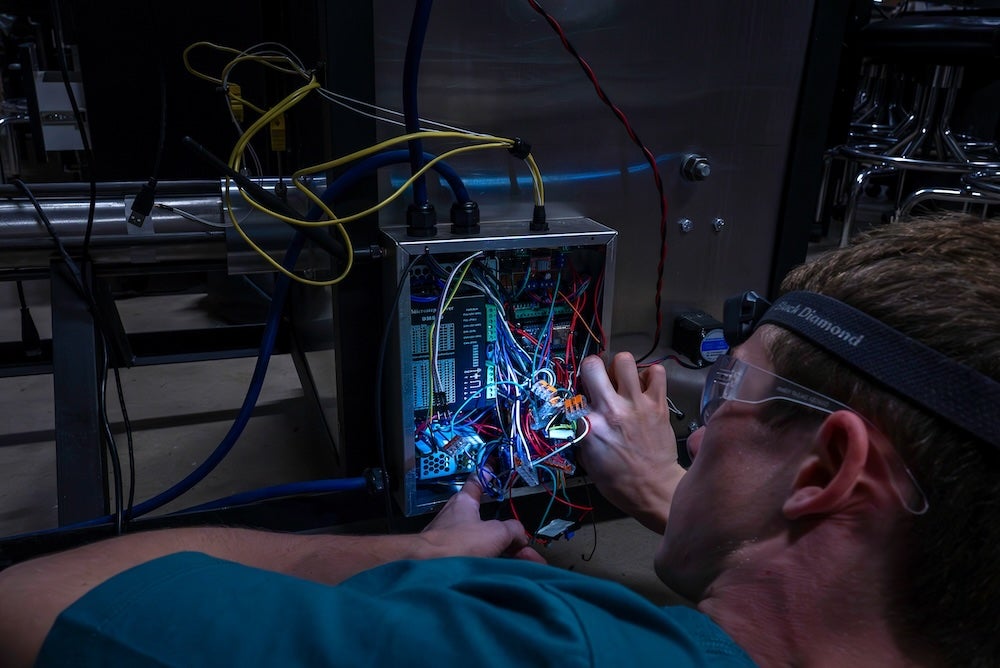

Metal powders are dangerous if inhaled, and working pressurized gas also adds another layer of safety considerations. The team worked with the environmental health and safety department at Rice to make sure it abided by all guidelines during testing. One of the safety specifications is that no one is allowed to be in the room while the system is in operation. To ensure safety, the team implemented a complex monitoring system and a three-part data logging system.

“We’ve implemented lots of security checks,” Guo said. “For example, there’s a particular hierarchy in which you can actually open up the switches. We communicate with the device wirelessly, so we’ve done a lot of code iteration to make sure that that works effectively.”

Case, who worked on the nozzle and heater design and on the software, said that one of the main takeaways from the project for him was the importance of having people with different areas of expertise working together; another takeaway was how critical it is to build more room for contingency in the project timeline. Hebda confirmed that for the team, it had been “pedal to the metal trying to fix the designs that were not going to work.”

“Inevitably, everything takes twice as long as you thought it would,” Hebda said, adding that working on the capstone design project made classroom knowledge come to life.

“You may be taking an engineering class on stress analysis and think, ‘I won’t be building a bridge any time soon,’” Hebda said. “But then you’re doing stress analysis on the tie rods of a pressure vessel, and seeing that be very real and getting real torque specs out of it. When you go fix your car, the book says what you tighten the bolts to. Now we’re the book ⎯ we’re coming up with what those values are. So doing that and being confident in those answers is really cool.”

French, who had a lot of hands-on hardware design experience as part of the engineering design minor, emphasized that “this team is just very motivated ⎯ it is a handpicked team and this is also a student-pitched project.”

“We are all people that signed up for a particularly hard project,” French said.

Team mentors are Ricardo Zednik, professor in the practice of materials science and nanoengineering, and David Trevas, a Rice mechanical engineering lecturer.

The team also thanked Gary Woods, professor in the practice in electrical and computer engineering; Ming Tang, associate professor of materials science and nanoengineering; Erik Welsh, Rice alumnus and chief technical officer/applications and systems manager at Octavo Systems; Joe Gesenhues, mechanical engineering department technician and shop manager; and Bruno Zamorano, materials and process engineer at Boeing.

- Image downloads:

-

https://news-network.rice.edu/news/files/2024/04/240409_AeroForge-OEDK-Team_Gustavo-6-b07017d462056997.jpg

CAPTION: Julianna Dickman (from left), Galio Guo, Davis Thames, Douglas Hebda, Grant Samara, Aasha Zinke, Garrett French and Eli Case (Photo by Gustavo Raskosky/Rice University)

https://news-network.rice.edu/news/files/2024/04/240409_AeroForge-OEDK-Team_Gustavo-5-b5ee441d671b1d53.jpg

(Photo by Gustavo Raskosky/Rice University)

https://news-network.rice.edu/news/files/2024/04/240409_AeroForge-OEDK-Team_Gustavo-3-4374859ed1e65968.jpg (Photo by Gustavo Raskosky/Rice University)