A large collaborative team led by the University of Texas at Austin with Rice University as a key partner was awarded $840 million to develop the next generation of high-performing semiconductor microsystems for the U.S. Department of Defense.

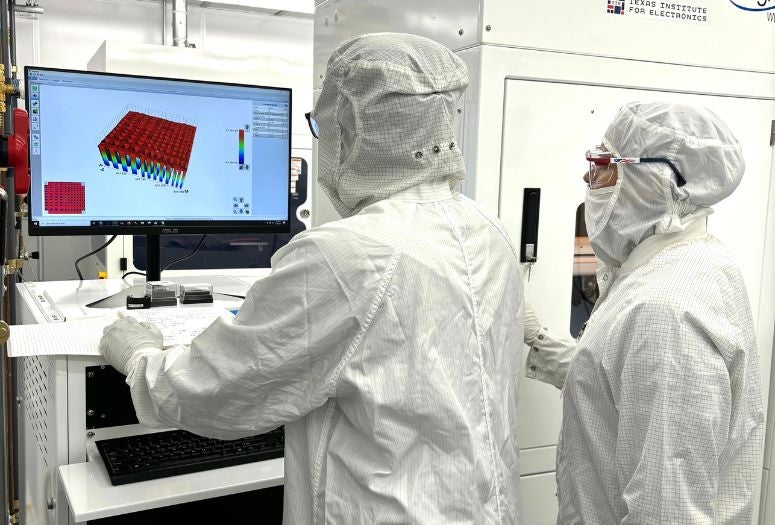

On July 18, the Defense Advanced Research Projects Agency (DARPA) selected UT’s semiconductor consortium, the Texas Institute for Electronics (TIE), to establish a national open-access R&D and prototyping fabrication facility to ensure America’s national security and global military leadership. The facility will enable DOD to create higher performance, lower power, lightweight and compact defense systems. Such technology could apply to radar, satellite imaging, unmanned aerial vehicles or other systems.

The new microsystem designs will be enabled by 3D heterogeneous integration (3DHI) — a semiconductor fabrication technology that integrates diverse materials and components into microsystems using precision assembly technologies.

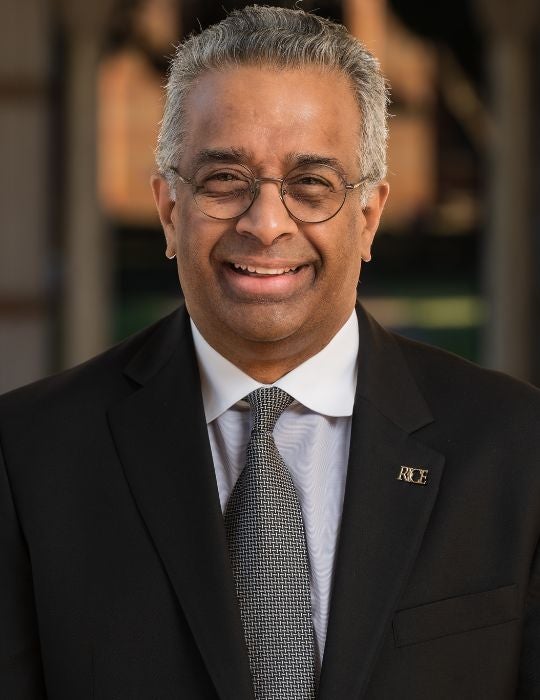

As a member of DARPA’s Next Generation Microelectronics Manufacturing (NGMM) team, the Rice researchers led by Ramamoorthy Ramesh, executive vice president for research, will focus on technologies for improving computing efficiency. An internationally recognized leader in materials science and physics with applications to energy, Ramesh emphasized the urgent need to enhance energy-efficient computing, highlighting Rice’s unique qualifications to contribute to the solution.

“Given the rapid growth of machine learning AI applications, there is a pressing need to fundamentally rethink current computing methodologies to advance the next generation of microelectronics. Rice University boasts world-class researchers with exceptional expertise in computer and electrical engineering poised to bolster this critical federally funded initiative,” Ramesh said. The company he co-founded, Kepler Computing, is a member of the NGMM team and utilizes ferroelectrics to develop energy-efficient approaches in computer memory and logic.

Other Rice researchers involved in the project include Lane Martin, director of the Rice Advanced Materials Institute; Ashok Veeraraghavan, chair of electrical and computer engineering; Pulickel Ajayan, the Benjamin M. and Mary Greenwood Anderson Professor of Engineering and founding chair of the materials science and nanoengineering department; Kaiyuan Yang, associate professor of electrical and computer engineering; and Guha Balakrishnan, assistant professor of electrical and computer engineering.

“By investing in leading-edge microelectronics manufacturing, we are helping secure this vulnerable supply chain, boosting our national security and global competitiveness and driving innovation in critical technologies,” said U.S. Sen. John Cornyn.

The project represents a total investment of $1.4 billion. The $840 million award from DARPA is a substantial return on the Texas Legislature’s $552 million investment in TIE, which has funded modernization of two UT fabrication facilities to strengthen long-term U.S. technology leadership. These facilities will be open to industry, academia and government, and will create dual-use innovations supporting the defense sector and the semiconductor industry, including startups, advancing technology for the betterment of society.

TIE’s NGMM team is composed of 32 defense electronics and leading commercial semiconductor companies and 18 nationally recognized academic institutions.

“TIE is tapping into the semiconductor talent available in Texas and nationally to build an outstanding team of semiconductor technologists and executives that can create this national center of excellence in 3DHI microsystems,” said S.V. Sreenivasan, TIE founder and chief technology officer and UT professor of mechanical engineering.

The program is composed of two phases — each 2.5 years in length. In Phase 1, TIE will establish the center’s infrastructure and basic capabilities. In Phase 2, the center will engineer 3DHI hardware prototypes important to the DOD and automate processes. It will also work with DARPA on separately funded design challenges.