When picturing next-generation wearables and robotics, the foam filling in your couch cushions is likely not the first thing that comes to mind.

However, Rice University engineers have shown that something as simple as the flow of air through the meshlike structure of open-cell foam can be used to perform digital computation, analog sensing and combined digital-analog control in soft textile-based wearable systems.

“In this work, we integrated material intelligence — the ability of materials to sense and respond to their environment — with circuit-driven logic using a surprisingly simple approach based on the flow of fluid through soft foams,” said Daniel Preston, assistant professor of mechanical engineering and corresponding author on a study about the research published in Advanced Functional Materials.

Pneumatic logic circuits in soft-bodied robots and wearables have been traditionally designed in ways that mirror electronic circuits, i.e. by linking together individual components such as resistors, capacitors, diodes and gates via connecting elements. Such conventional architectures rely on interconnected logic gates — basic building blocks in digital systems that turn one or more than one input into a single output.

In previous work, the Preston Innovation Laboratory developed a method for electronics-free control of textile wearables using pneumatic logic circuits. However, this initial approach did not rely on the properties intrinsic to soft materials in order to maximize circuit design efficiency.

“The more complex a task or operation, the greater the number of logic gates typically required,” Preston explained.

In applications, this could translate into devices that are heavier, more expensive and difficult to make and more susceptible to failure. To bypass the issue, the researchers figured out how to use pressure differences created by air flowing through the microscopic pores in foam sheets in order to perform complex pneumatic computations and control tasks with a greater economy of circuit design.

“Here, we show that the properties of soft materials themselves — such as the sponginess or porosity of foam sheets — can be leveraged to achieve fluidic control tasks such as sensing the amount of force applied by a user or converting digital pressure signals to analog signals, thereby reducing the reliance on fluidic logic gates and simplifying operation,” said Anoop Rajappan, lead author on the study and a research scientist at Rice during the course of the project.

Unlike liquids, the density of air changes with pressure, which makes the modeling of airflow through foam sheets more complex. Nonetheless, the researchers tackled the challenge head-on.

“We developed a theoretical framework for analyzing gas flow through porous materials, created new experimental techniques to measure the fluidic properties of foam and finally generated a model for the change in fluidic resistance of foam with applied force,” Rajappan said.

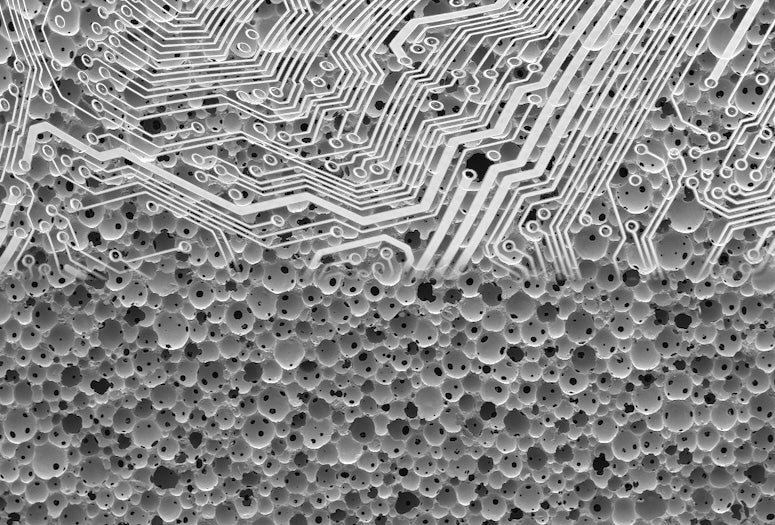

The researchers designed foam-based fluidic resistors — devices that restrict airflow in pneumatic circuits, much like how electronic resistors limit current flow in electronic circuits. The resistors can be used to create two-dimensional pneumatic logic circuits that can be embedded in textile-based wearable devices.

(Image courtesy of the Preston Innovation Lab/Rice University)

“By redesigning circuit components such as resistors to leverage the fluidic properties of soft materials such as foam, we can build reliable and streamlined soft robots and wearable devices powered by pneumatics that are less dependent on heavy, bulky or rigid components such as motors and batteries,” Rajappan said. “Wearable robotic devices could, for instance, provide assistance to users with mobility limitations, and building wearables out of textiles and powering them using compressed air can make them comfortable, lightweight, low-cost and unobtrusive for the user.”

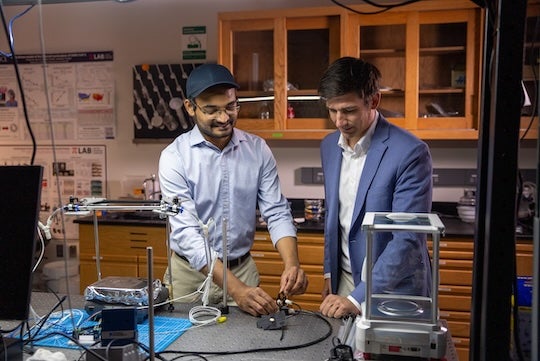

In addition to Preston and Rajappan, other authors on the study include Zhen Liu, Faye Yap and Rawand Rasheed. Rajappan, Liu and Yap have accepted offers to tenure-track assistant professor positions at Tulane University, the University of Texas at Dallas and the University of Hawaii, respectively. Rasheed is CEO of Helix Earth Technologies, a startup spun out of Preston’s lab.

(Image courtesy of the Preston Innovation Lab/Rice University)

“Our work at Rice is making real contributions across multiple fields, and I am glad so many of our students continue to do so, in academia, industry and even their own companies, after training in our program,” Preston said.

The research was supported by the Rice Academy of Fellows, the U.S. Department of Energy (DE-SC0014664), the Shared Equipment Authority at Rice and the National Science Foundation (CMMI-2144809).

- Peer-reviewed paper:

-

Embedded Fluidic Sensing and Control with Soft Open-Cell Foams | Advanced Functional Materials | DOI: 10.1002/adfm.202403379

Authors: Anoop Rajappan, Zhen Liu, Te Faye Yap, Rawand Rasheed and Daniel Preston

https://doi.org/10.1002/adfm.202403379 - Image downloads:

-

https://news-network.rice.edu/news/files/2024/07/220822_preston-lab-mechanical-engineering_martin-14.jpg

CAPTION: Anoop Rajappan (left) and Daniel Preston (Photo by Brandon Martin/Rice University)

https://news-network.rice.edu/news/files/2024/07/foam-resistor-cross_section.jpg

CAPTION: Cross section of a foam-based fluidic resistor (left); microscope view of foam sheet cross section (right). (Image courtesy of the Preston Innovation Lab/Rice University)

https://news-network.rice.edu/news/files/2024/07/bending-actuator.jpg

CAPTION: Push button-activated foam-based fluidic actuator; varying levels of force cause corresponding levels of actuation. (Image courtesy of the Preston Innovation Lab/Rice University)

https://news-network.rice.edu/news/files/2024/07/Preston_digital-to-analog.jpg

CAPTION: Foam-based fluidic actuator controlled via integrated digital-to-analog converter.

(Image courtesy of the Preston Innovation Lab/Rice University)

https://news-network.rice.edu/news/files/2024/07/signal_transmission_fluidics.jpg

CAPTION: Foam-based fluidic circuits can be used to transmit data via haptic cues.

(Image courtesy of the Preston Innovation Lab/Rice University)