HOUSTON – (Jan. 25, 2022) – Concrete fractures that are invisible to the naked eye stand out in images produced through a technique created at Rice University.

A collaboration between research groups at Rice and the Kuwait Institute for Scientific Research discovered by chance that common Portland cement contains microscopic crystals of silicon that emit near-infrared fluorescence when illuminated with visible light. That led to two realizations. The first was that the exact wavelength of the emission can be used to identify the particular type of cement in a structure.

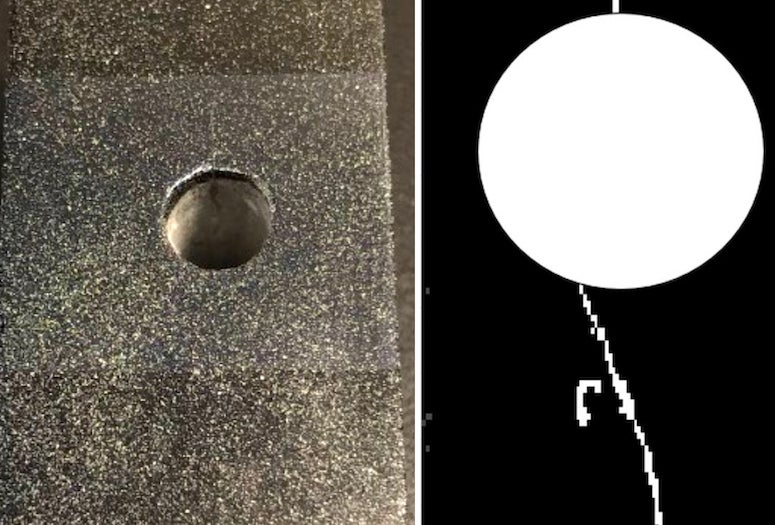

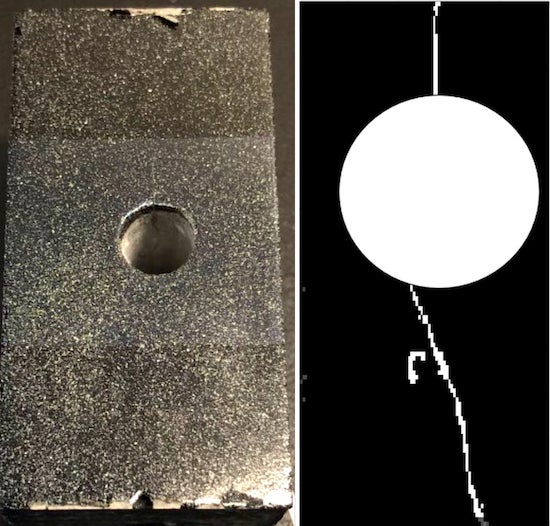

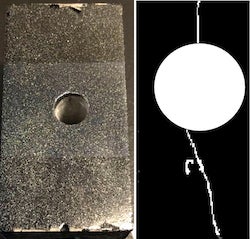

The second and perhaps more important is that the near-infrared emission can reveal even very small cracks in cement or concrete. The trick is to apply a thin coat of opaque paint to the concrete when it’s new. In near-infrared scans, intact concrete appears black and glowing light reveals the tiniest of cracks.

The open-access study by the labs of Rice chemist Bruce Weisman, Rice structural engineer Satish Nagarajaiah and Kuwait Institute of Scientific Research investigator Jafarali Parol appears in Scientific Reports.

Wei Meng, the paper’s first author, found the phenomenon while pursuing the Rice team’s long-standing work on optical strain sensing with carbon nanotubes.

“This arose from a project in which we were trying to apply our strain measurement technique to cement and concrete, but we ran into an unexpected problem when we illuminated a specimen coated with a nanotube film,” said Weisman, a pioneer in nanotube spectroscopy. “We found that one of the peaks in our film spectrum was obscured by much stronger emission coming from somewhere. We never expected it would be from the cement itself.”

He said he was not aware of any other lab reporting the phenomenon. “Eventually, we were able to mask off the specimen so the emission didn’t interfere with our strain measurement,” he said. “But we kept in the backs of our minds that maybe this could be interesting on its own.”

The emission’s unusual spectral signature let the researchers deduce that the source was pure silicon crystals. “Minerals called silicates are major components of cement, and we hypothesized that during the high temperature production process, very small amounts decompose to form microscopic silicon crystals,” Weisman said. “Their emission wavelength tells us that they’re larger than about 10 nanometers, but they can’t be much bigger or people would have noticed them long ago.”

Meng experimented on small concrete blocks painted black and with holes drilled in the middle. These served as focal points to form microcracks that would propagate outward when the blocks were compressed, also cracking the paint. He found the fluorescent signal came through the tiny cracks and could easily be mapped with a raster-scanning laser.

“Concrete structures need monitoring, and this is one way of monitoring them,” said Nagarajaiah, who specializes in infrastructure/structural monitoring, system identification, damage detection and adaptive stiffness structure systems to withstand seismic events. “Getting a clear idea of where cracks are can be quite important in structures, especially in the critical places where we know they’re going to be stressed.”

He said the benefits of better crack detection could extend beyond bridges and buildings to containment structures at nuclear power plants or on ships or the insides of wells and pipelines that are difficult to access.

The researchers said a practical approach is to shine light on critical structures and photograph them using a near-infrared camera and narrow-band spectral filter.

“Cement cracking can be an early symptom of failure, so people who are concerned with the structural integrity and safety of concrete structures want to detect microcracks before they grow,” Weisman said.

Rice research scientist Sergei Bachilo is co-author of the study. Nagarajaiah is a professor of civil and environmental engineering, of materials science and nanoengineering, and of mechanical engineering. Weisman is a professor of chemistry and of materials science and nanoengineering.

The Kuwait Institute for Scientific Research and the National Science Foundation (CHE-1803066) supported the research.

Image for download:

https://news-network.rice.edu/news/files/2022/01/0131_CEMENT-1-WEB.jpg

Small cracks in a stressed, painted cement block are barely visible under ambient lighting (left panel) but show up clearly in the near-infrared image at right. Rice University scientists discovered silicon crystals in Portland cement emit fluorescent, infrared light that can reveal early damage in concrete that might otherwise be overlooked. (Credit: Weisman Research Group/Nagarajaiah Group/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 4,052 undergraduates and 3,484 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 1 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.