A bit of brushing may be the secret to making better rechargeable lithium batteries.

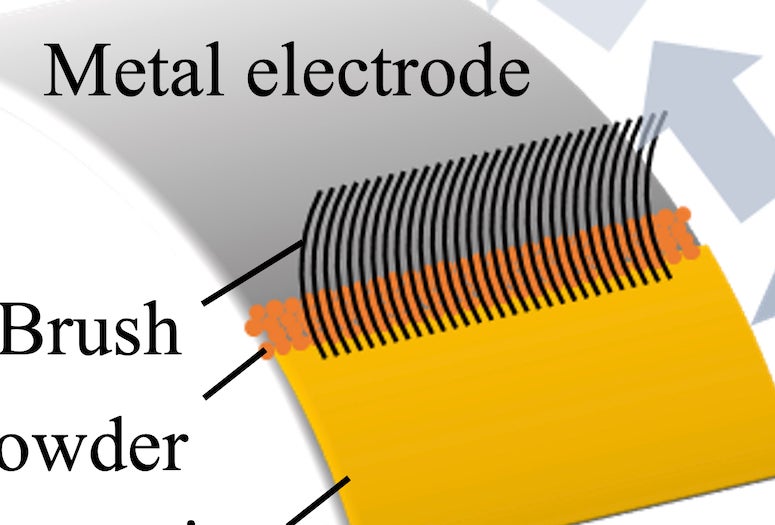

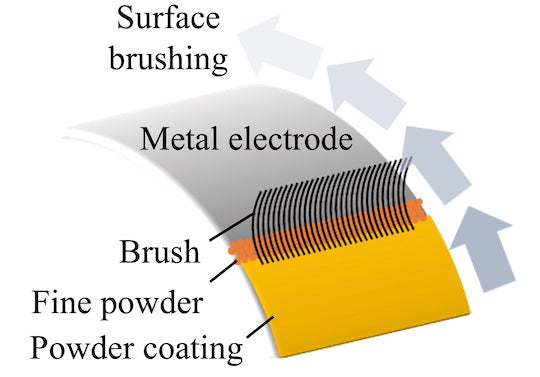

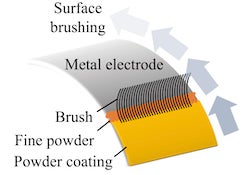

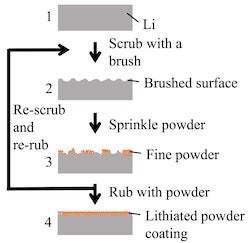

The Rice University lab of chemist James Tour introduced a technique to tune the surface of anodes for batteries by simply brushing powders into them. The powder adheres to the anode and becomes a thin, lithiated coating that effectively prevents the formation of damaging dendrites.

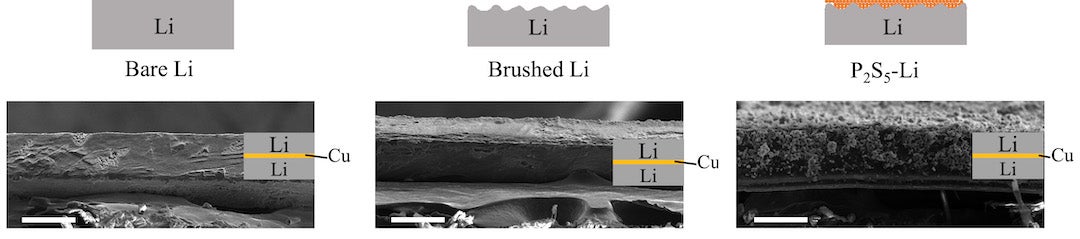

A powder of phosphorus and sulfur ground into the surface of lithium metal foil demonstrated its surface energy can be tuned without the need for toxic solvents. Anodes so modified and paired with lithium-iron-phosphate-oxide cathodes in test cells showed they retained 70% more capacity after 340 charge-discharge cycles than off-the-shelf batteries.

The study appears in Advanced Materials.

“This would simplify the manufacture of high-capacity batteries while greatly improving them,” Tour said. “Sanding these powdered solids into a lithium metal anode dramatically reduces dendrite formation that can short circuit a battery, as well as the accelerated consumption of the materials.”

Lead author and Rice graduate student Weiyin Chen and his lab colleagues applied the necessary elbow grease to test a variety of powder candidates on their electrodes. They first brushed the surface to give it texture, then brushed in powder to create the fine film that reacts with the lithium metal and forms a solid passivation layer.

Chen and co-author Rodrigo Salvatierra, a former postdoctoral researcher and now an academic visitor in the Tour lab, constructed test batteries and determined the treated anodes retained ultralow polarization — another damaging characteristic for lithium-ion batteries — for more than 4,000 hours, about eight times longer than bare lithium anodes.

Tour said the powders effectively tune the surface energy of the electrodes, making for a more uniform behavior across the material.

“This provides a metal composite surface that prevents the loss of lithium metal from the anode, a common problem in lithium metal batteries,” Tour said. “Lithium metal batteries far exceed the capacity of traditional lithium-ion batteries, but the lithium metal is often difficult to repeatedly recharge.”

“The powder at the lithium metal surface produces an artificial passivation layer that improves the stability throughout the charge-discharge cycles,” Chen said. “Using this brush-on method, the metal surface is stabilized so that it can be safely recharged.”

To show the technique may have wider application, the lab also ground powder into a sodium electrode and discovered the process greatly stabilized its voltage overpotential.

The study aligns with the recent discovery by Tour and Rice mechanical engineer C. Fred Higgs III that sanding certain powders into surfaces can make them superhydrophobic, or highly resistant to water.

Co-authors of the paper are Rice alums John Li and Duy Luong; graduate students Jacob Beckham, Nghi La and Jianan Xu, and academic visitor Victor Li. Tour is the T.T. and W.F. Chao Chair in Chemistry as well as a professor of computer science and of materials science and nanoengineering at Rice.

The Air Force Office of Scientific Research (FA9550-19-1-0296) supported the research.

- Peer-reviewed research

-

Brushed Metals for Rechargeable Metal Batteries: https://onlinelibrary.wiley.com/doi/10.1002/adma.202202668

- Images for download

-

https://news-network.rice.edu/news/files/2022/08/0822_LITHIUM-1-WEB.jpg

Brushing metal powders into the surface of lithium anodes shows promise to curtail the threat of dendrites that damage recyclable batteries, according to scientists at Rice University. (Credit: Tour Group/Rice University)

https://news-network.rice.edu/news/files/2022/08/0822_LITHIUM-2b-WEB.jpg

A several-step process without toxic solvents that adds a lithiated film to the anodes of lithium-ion batteries promises to prevent the formation of damaging dendrites, according to Rice University scientists. (Credit: Tour Group/Rice University)

https://news-network.rice.edu/news/files/2022/08/0822_LITHIUM-3-WEB.jpg

Scanning electron microscope images show a sequence of lithium foils treated by scientists at Rice University. Brushing metal powder into lithium anodes for rechargeable batteries can prevent the formation of damaging dendrites. The scale bars represent 100 microns. (Credit: Tour Group/Rice University)

https://news-network.rice.edu/news/files/2022/08/0822_LITHIUM-4-WEB.jpg

Rice University scientists have discovered that brushing powdered phosphorus and sulfur into lithium anodes helps keep them from forming damaging dendrites in rechargeable batteries. From left: James Tour, Weiyin Chen and Rodrigo Salvatierra. (Credit: Rice University)

- Related materials

-

Water can’t touch this sanded, powdered surface: https://news.rice.edu/news/2022/water-cant-touch-sanded-powdered-surface

Tour Group: https://www.jmtour.com

Department of Chemistry: https://chemistry.rice.edu

Wiess School of Natural Sciences: https://naturalsciences.rice.edu

- About Rice

-

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 4,240 undergraduates and 3,972 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 1 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.