Editor’s note: Links to a video and images for download appear at the end of this release.

David Ruth

713-348-6327

david@rice.edu

Mike Williams

713-348-6728

mikewilliams@rice.edu

Atomic placement of elements counts for strong concrete

Rice University researchers model particulate systems to determine their qualities

HOUSTON – (Jan. 8, 2015) – Even when building big, every atom matters, according to new research on particle-based materials at Rice University.

Rice researchers Rouzbeh Shahsavari and Saroosh Jalilvand have published a study showing what happens at the nanoscale when “structurally complex” materials like concrete — a random jumble of elements rather than an ordered crystal — rub against each other. The scratches they leave behind can say a lot about their characteristics.

The researchers are the first to run sophisticated calculations that show how atomic-level forces affect the mechanical properties of a complex particle-based material. Their techniques suggest new ways to fine-tune the chemistry of such materials to make them less prone to cracking and more suitable for specific applications.

The research appears in the American Chemical Society journal Applied Materials and Interfaces.

The study used calcium-silicate-hydrate (C-S-H), aka cement, as a model particulate system. Shahsavari became quite familiar with C-S-H while participating in construction of the first atomic-scale models of the material.

C-S-H is the glue that binds the small rocks, gravel and sand in concrete. Though it looks like a paste before hardening, it consists of discrete nanoscale particles. The van der Waals and Coulombic forces that influence the interactions between the C-S-H and the larger particles are the key to the material’s overall strength and fracture properties, said Shahsavari. He decided to take a close look at those and other nanoscale mechanisms.

“Classical studies of friction on materials have been around for centuries,” he said. “It is known that if you make a surface rough, friction is going to increase. That’s a common technique in industry to prevent sliding: Rough surfaces block each other.

“What we discovered is that, besides those common mechanical roughening techniques, modulation of surface chemistry, which is less intuitive, can significantly affect the friction and thus the mechanical properties of the particulate system.”

Shahsavari said it’s a misconception that the bulk amount of a single element — for example, calcium in C-S-H — directly controls the mechanical properties of a particulate system. “We found that what controls properties inside particles could be completely different from what controls their surface interactions,” he said. While more calcium content at the surface would improve friction and thus the strength of the assembly, lower calcium content would benefit the strength of individual particles.

“This may seem contradictory, but it suggests that to achieve optimum mechanical properties for a particle system, new synthetic and processing conditions must be devised to place the elements in the right places,” he said.

The researchers also found the contribution of natural van der Waals attraction between molecules to be far more significant than Coulombic (electrostatic) forces in C-S-H. That, too, was primarily due to calcium, Shahsavari said.

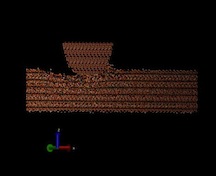

To test their theories, Shahsavari and Jalilvand built computer models of rough C-S-H and smooth tobermorite. They dragged a virtual tip of the former across the top of the latter, scratching the surface to see how hard they would have to push its atoms to displace them. Their scratch simulations allowed them to decode the key forces and mechanics involved as well as to predict the inherent fracture toughness of tobermorite, numbers borne out by others’ experiments.

Shahsavari said atomic-level analysis could help improve a broad range of non-crystalline materials, including ceramics, sands, powders, grains and colloids.

Jalilvand is a former graduate student in Shahsavari’s group at Rice and is now a Ph.D. student at University College Dublin. Shahsavari is an assistant professor of civil and environmental engineering and of materials science and nanoengineering and a member of the Richard E. Smalley Institute for Nanoscale Science and Technology at Rice.

The National Science Foundation (NSF) supported the research. Supercomputer resources were provided by the National Institutes of Health and an IBM Shared University Research Award in partnership with CISCO, Qlogic and Adaptive Computing, and the NSF-funded Data Analysis and Visualization Cyber Infrastructure administered by Rice’s Ken Kennedy Institute for Information Technology.

-30-

Read the abstract at http://pubs.acs.org/doi/abs/10.1021/am506411h

See a video simulation at http://youtu.be/iH9Jd3TProY

Follow Rice News and Media Relations via Twitter @RiceUNews

Related Materials:

Shahsavari Group: http://rouzbeh.rice.edu/default.aspx

George R. Brown School of Engineering: http://engineering.rice.edu

Images for download:

https://news2.rice.edu/files/2015/01/0112_PARTICLES-1-WEB.jpg

A calcium-silicate-hydrate (aka cement) tip hovers above a smooth tobermorite surface in a computer simulation by Rice University scientists. The researchers studied how atomic-level forces in particulate systems interact when friction is applied. Their calculations show such materials can be improved for specific applications by controlling the materials’ chemical binding properties. (Credit: Shahsavari Group/Rice University)

https://news2.rice.edu/files/2015/01/0112_PARTICLES-2-WEB.jpg

A top-down look at the tip of a virtual cement probe shows the position of atoms, dominated by calcium and silicate. Researchers at Rice University used simulations to show the chemical makeup of particulate systems affects their material strength by simulating friction with various surfaces. (Credit: Shahsavari Group/Rice University)

https://news2.rice.edu/files/2015/01/0112_PARTICLES-3-web.jpg

Rouzbeh Shahsavari. Photo by Jeff Fitlow

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,920 undergraduates and 2,567 graduate students, Rice’s undergraduate student-to-faculty ratio is just over 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is highly ranked for best quality of life by the Princeton Review and for best value among private universities by Kiplinger’s Personal Finance. To read “What they’re saying about Rice,” go here.