Rice, MIT research could help maximize strength of body armor for soldiers, aerospace materials

In the macro world, it’s easy to see what happens when a bullet hits an object. But what happens at the nanoscale with very tiny bullets?

A Rice University lab, in collaboration with researchers at the Massachusetts Institute of Technology and its Institute for Soldier Nanotechnologies, decided to find out by creating the nanoscale target materials, the microscale ammo and even the method for firing them.

Ned Thomas, dean of the George R. Brown School of Engineering at Rice and a materials scientist, holds a polyurethane disk with the bullets it stopped and sealed inside. Thomas is leading an investigation into the characteristics of such materials at the nanoscale. Photo by Tommy LaVergne

In the process, they gathered a surprising amount of information about how materials called block copolymers dissipate the strain of sudden impact.

The goal of the researchers is to find novel ways to make materials more impervious to deformation or failure for stronger and lighter body armor, jet engine turbine blades for aircraft, and for cladding to protect spacecraft and satellites from micrometeorites and space junk. Their work was detailed in the online journal Nature Communications.

The group was led by Rice materials scientist Ned Thomas, the William and Stephanie Sick Dean of Rice’s George R. Brown School of Engineering, and Rice research scientist and lead author Jae-Hwang Lee.

The researchers were inspired by their observations in macroscopic ballistic tests in which a complex multiblock copolymer polyurethane material showed the ability to not only stop a 9 mm bullet but also seal the entryway behind it.

“The polymer has actually arrested the bullet and sealed it,” Thomas said, holding a hockey puck-sized piece of clear plastic with three bullets firmly embedded. “There’s no macroscopic damage; the material hasn’t failed; it hasn’t cracked. You can still see through it. This would be a great ballistic windshield material.

“We want to find out why this polyurethane works the way it does. Theoretically, no one understood why this particular kind of material – which has nanoscale features of glassy and rubbery domains – would be so good at dissipating energy,” he said.

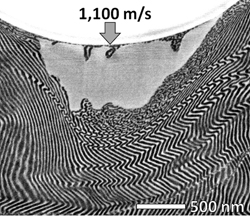

An electron microscope image of a silica sphere fired edge-on into a block copolymer shows how the glassy and rubbery layers contorted as they dissipated the strain from the projectile. Directly in front of the sphere, heat from the shot melted the copolymer into a homogeneous liquid. Thomas Lab/Rice University

One problem, Thomas said, is that cutting the polymer to analyze it on the nanoscale “would take days.” The researchers sought a model material that would react similarly at the nanoscale and could be analyzed much faster. They found one in a polystyrene-polydimethylsiloxane diblock-copolymer. The material self-assembles into alternating 20-nanometer layers of glassy and rubbery polymers. Under a scanning electron microscope, it looks like corduroy; after the test, the disruption pattern from impact can be clearly seen.

The results showed several expected deformation mechanisms and the unexpected result that for sufficiently high velocities, the layered material melted into a homogeneous liquid that seemed to help arrest the projectile and, like the polymer, seal its entry path. The copolymer also behaved differently depending on where the spheres hit. The material showed the best ability to dissipate the energy of impact when spheres were fired perpendicular to the layers, Thomas said.

Rice University scientists Ned Thomas, dean of the George R. Brown School of Engineering, and Jae-Hwang Lee show the polyurethane disk that stopped three bullets – and sealed them inside. The experiment inspired research to learn why the material works so well at the nanoscale. Photo by Tommy LaVergne

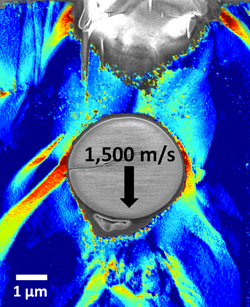

Testing their ideas took special equipment. The research team came up with a miniaturized test method, dubbed the laser-induced projectile impact test (LIPIT), that uses a laser pulse to fire glass spheres about 3 microns in diameter. The spheres sit on one side of a thin absorbing film facing the target. When a pulse hits the film, the energy causes it to vaporize and the spheres to fly off, hitting speeds between .5 and 5 kilometers per second. Since the kinetic energy scales with velocity squared, the factor of 10 in speed translates to a factor of 100 in impact energy, Thomas said.

Lee calculated the impact in real-world terms: The spheres strike their target 2,000 times faster than an apple falling one meter hits the ground, but with a million times less force. However, because the sphere’s impact area is so concentrated, the impact energy is more than 760 times greater. That leaves a mark, he said.

An electron microscope image shows the effects of a silica sphere less than a 10th the width of a human hair on a block copolymer. The sphere was fired at the copolymer at 1,500 meters per second to study the effect of such impacts on advanced materials being developed to protect soldiers, aircraft and spacecraft. Compressed layers of the copolymer appear in red and orange. Thomas Lab/Rice University

The team tested their materials in two ways: horizontally, with the impact perpendicular to the micro grain, and vertically, straight into the layered edges. They found the horizontal material best at stopping projectiles, perhaps because the layers reflect part of the incident shock wave. Beyond the melt zone in front of the projectile, the layers showed the ability to deform without breaking, which led to improved energy absorption.

“After the impact we can go in and cross-section the structure and see how deep the bullet got, and see what happened to these nice parallel layers,” Thomas said. “They tell the story of the evolution of penetration of the projectile and help us understand what mechanisms, at the nanoscale, may be taking place in order for this to be such a great, high-performance, lightweight protection material.”

Thomas would like to extend LIPIT testing to other lightweight, nanostructured materials like boron nitride, carbon nanotube-reinforced composites and graphite and graphene-based materials. The ultimate goal, he said, is to accelerate the design of metamaterials with precise control of their nano- and microstructures for a variety of applications.

Co-authors of the paper are graduate students David Veysset, Jonathan Singer, Gagan Saini and Keith Nelson at MIT; Markus Retsch of MIT and the University of Bayreuth, Germany; and Tomas Pezeril of MIT and the Université du Maine, Le Mans, France.

The research was supported by the U.S. Army Research Office.

Leave a Reply